Carrier & Substrate Materials

Carriers & Substrates for Active Ingredients

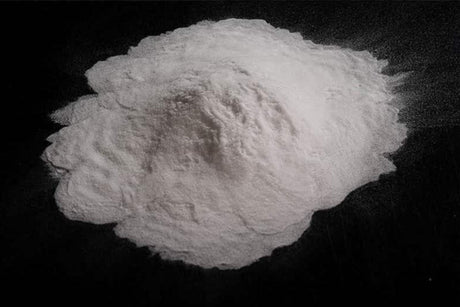

Mineral-based carriers provide consistent flow, dispersion, and stability for dry and encapsulated actives. Engineered for use in agriculture, pharmaceuticals, food additives, and chemical formulations, these materials improve the delivery, shelf life, and handling of powders and granules without compromising purity or performance.

Common Uses

-

Dry carriers: Uniform dispersion of micronutrients, pesticides, enzymes, or flavor compounds.

-

Encapsulation & stabilization: Controlled release and protection of moisture-sensitive or volatile actives.

-

Flow enhancement: Reduces caking, improves blend uniformity, and supports automated filling systems.

-

Surface coating: Creates consistent coverage for powdered actives and coatings.

Typical Materials

-

Attapulgite clay: Excellent adsorption and rheology control for suspension and granule systems.

-

Silica: High surface area and purity for food and pharmaceutical carriers.

-

Alumina: Chemically inert and thermally stable for catalysts and fine chemical formulations.

-

Zeolite: Moisture-controlling carrier ideal for biologically active or hygroscopic compounds.

Example Application

A feed supplement manufacturer used precipitated silica as a carrier to evenly distribute a liquid vitamin concentrate into a free-flowing powder. The resulting blend improved dosing accuracy, reduced caking during storage, and maintained uniform nutrient distribution through packaging and delivery.

Get Expert Support

Need help selecting the right carrier material or optimizing loading ratios? Our team can assist with formulation and bulk supply options.

Get Expert Support or Bulk Quotes

Request a Custom Quote

Request a Custom Quote